Gift-giving has long been a cherished tradition in Vietnamese culture, symbolizing deep relationships and mutual appreciation. As gifts play an important role in building connections, the demand for gift boxes has significantly increased to enhance the presentation of these meaningful items. For businesses, the production process of bulk gift boxes is often a topic of great interest, especially when customized printing is involved.

Selecting materials for bulk gift boxes

The choice of materials directly affects the quality of the final product. When selecting paper for your gift boxes, there are three key factors to consider:

Paper type

Different types of paper can be used for gift boxes, such as Couche, Ivory, Bristol, Art paper, and Kraft. To ensure durability and create visually appealing boxes, these papers are often combined with chipboard (rigid paperboard). For those unsure of which paper to choose, you can explore the most common types of printing paper suitable for gift boxes in bulk.

Paper weight

Paper weight, or grammage, is another crucial element as it directly impacts the sturdiness of the box. A higher paper weight usually means a stronger box, but it also increases production costs. Selecting the right paper weight is essential to balancing durability with the aesthetics of the gift box.

Paper source

The origin of the paper is often a concern for clients ordering gift boxes in bulk. Common questions include: Is the paper imported? Does it meet quality standards? Some customers also pay attention to the safety and environmental standards of the paper, such as FSC or PEFC certifications, ensuring the materials are both eco-friendly and safe for use.

Choosing the design and structure for bulk gift boxes

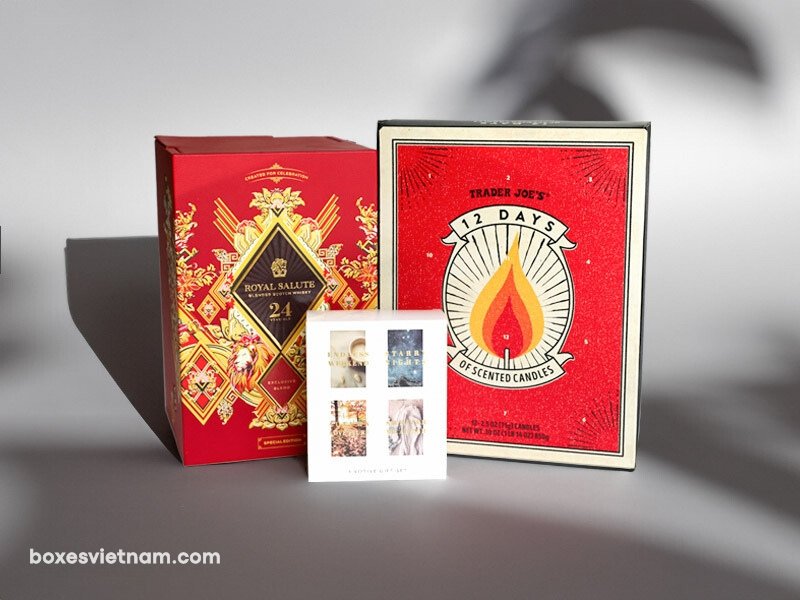

The design and structure of the gift box have a significant impact on its visual appeal and the unboxing experience for the recipient. Popular types of bulk gift boxes include:

Lid and base gift boxes

Lid and base gift boxes are a popular choice for bulk orders due to their sturdy structure. These boxes feature a separate lid and base, offering excellent durability and shock resistance. Additionally, their easy-to-use design ensures a convenient unboxing experience.

>>> Custom big gift boxes with lids for elegant gift presentation

Magnetic closure gift boxes

Magnetic closure gift boxes stand out for their sleek design and practicality. The lid is attached to the body, secured with a magnetic closure, which not only makes them easy to open but also ensures that the contents remain well-protected during transport.

Drawer-style gift boxes

Drawer-style gift boxes offer a touch of luxury with their unique sliding tray mechanism. The tray slides out horizontally from the sleeve, providing an elegant presentation for smaller items such as jewelry, accessories, or premium gifts. This design adds sophistication and is perfect for brands seeking to create a memorable unboxing experience for their customers.

Designing and printing bulk gift boxes

Design and printing are key factors that differentiate one gift box from another. Not only should the box be visually appealing, but it must also reflect the brand’s identity. Elements such as color, logo, slogan, and product information should be strategically placed to enhance brand recognition.

Currently, minimalistic designs with soft, elegant colors are trending. Once the design is finalized, the printing process begins. Modern printing techniques bring these designs to life, making your gift boxes stand out and attract attention. High-quality printing ensures that all essential details are clear and precise, further increasing the box’s value as a branding tool.

Finalizing and finishing techniques in gift box production

The final step in the production of gift boxes involves adding finishing touches. Some common finishing techniques include:

Foil stamping

Adds a metallic sheen to specific areas, highlighting logos or text for a luxurious effect.

Embossing and debossing

Creates a raised or recessed effect on the box surface, adding texture and sophistication.

>>> 7 Common mistakes to avoid when designing luxury box gifts

UV coating

Protects the surface while adding shine to certain areas, enhancing visual appeal.

In addition, techniques such as lamination, die-cutting, and window patching can increase the durability and uniqueness of the box. At this stage, the box is assembled, glued, or fitted with accessories like ribbons or bows. Finally, each product undergoes a quality check before being delivered to the customer.

The above outlines the basic process in the production of gift boxes. Achieving a high-quality product requires numerous additional steps. Let us address your needs with comprehensive gift packaging solutions, covering design, printing, and complete production.

KHANG THANH – HOUSE OF PACKAGING

Tel: +84 (0) 77 8878 222

Email: info@khangthanh.com