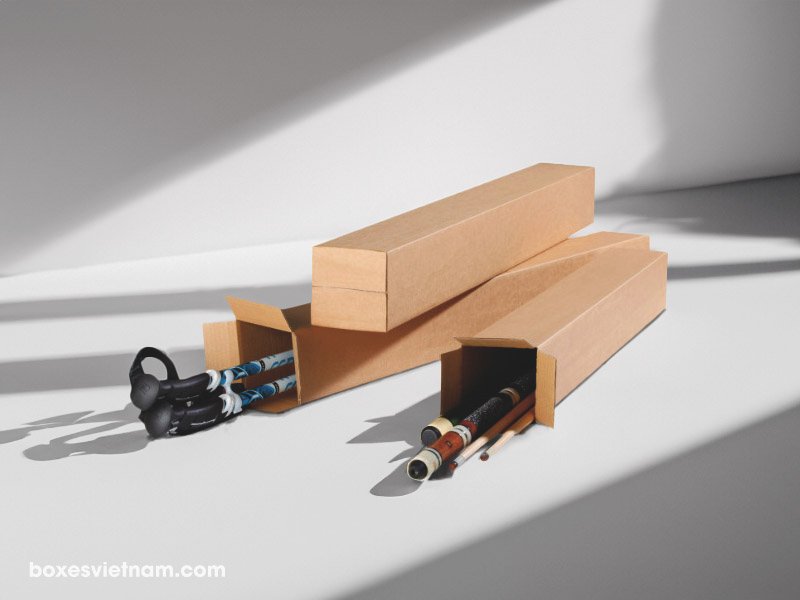

For goods with long, tall shapes and narrow widths, long cardboard box for shipping are the optimal choice.

Understanding an important of the right shipping packaging plays a key role in the goods transportation process, Khang Thanh introduces you to the points to keep in mind to produce satisfactory long shipping boxes.

1. Determine the size and weight of the goods

To produce long cardboard boxes that suit your needs, there are two criteria to avoid waste and maximize the product protection ability of the shipping box: size and weight of the goods.

Size

Firstly, you need to measure the size of the items to be transported accurately. Measure the object’s length, width and height, then increase the shipping box size by 2-3cm to insert paper splints, shaped trays or bubble wrap to protect the product.

Besides cardboard boxes with typical lengths, you need to accurately measure the size of the goods to adjust and customize the long box for shipping.

Weight

On the other hand, measuring the weight of products is an essential part of deciding the thickness of corrugated materials used for shipping boxes. The long packaging boxes must have standard rigidity to maximize the protective function.

2. Material and thickness of long shipping boxes

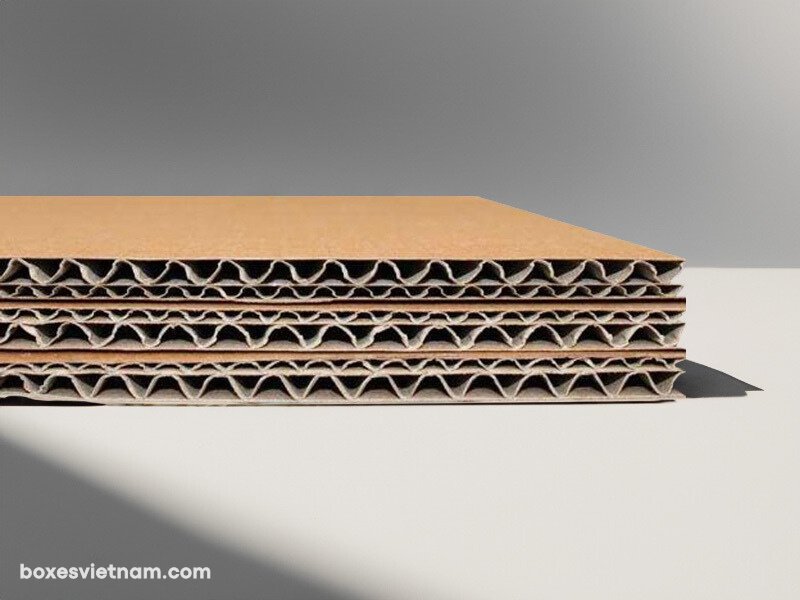

Cardboard boxes are made from many layers of paper and corrugated pressed together, and the corrugated thickness will determine the bearing capacity.

Khang Thanh introduces you to 3 popular types of long cardboard boxes that are easy to order in Vietnam and have reasonable prices when produced in large quantities:

- 3-layer long boxes for shipping: Suitable for thin, light objects and short transport routes.

- 5-layer long packing boxes: These are commonly used for most types of goods and are popular because of their high durability.

- 7-layer long shipping boxes: Typically used for heavy or fragile items that require maximum protection.

3. Design a reasonable shipping box structure

Designing a reasonably long box for shipping structure is critical to ensure that goods are best protected during transportation.

By assessment and analysis, the technical department at the paper packaging manufacturing company can decide:

- Suitable corrugated materials

- Reasonable corrugated direction distribution to increase durability and hardness

- Decide how to produce the finished product (using glue or staples) to ensure absolute protection

- Add additional shaping trays, foam trays or paper splints if necessary

>>> 5 layer carton boxes – Safe and comprehensive packaging of goods

4. Choose a skilled cardboard manufacturing company with competitive prices

A skilled cardboard manufacturing company will offer comprehensive packaging solutions that help long shipping boxes meet standards and save costs.

With nearly 20 years of operation in the paper packaging field, Khang Thanh is proud to provide secondary packaging boxes that meet export standards.

5. Benefits of producing long shipping box

Ability to protect goods

Long and thin items will be more suitable for long cartons than regular square or rectangular cartons.

Thanks to its narrow width and high length, this shipping box structure will fit objects tightly, reducing vibration and impact and providing maximum protection for goods during transportation.

Cost-effective shipping packaging

Compared to size, although this type of carton has an outstanding length, the width is very narrow to suit specific goods. Therefore, compared to the spread size, long cartons will be smaller, significantly reducing costs.

Sustainable long cardboard boxes

Cardboard boxes are a highly recyclable and reusable product. After transporting goods, users can completely reuse the box for other personal purposes such as storing belongings, moving house, moving office…

In addition, long cartons made from FSC wood will bring long-term sustainable benefits to the supply chain from suppliers, manufacturing companies and customers.

>>> Fasteners packaging solution: Choosing the optimal box types

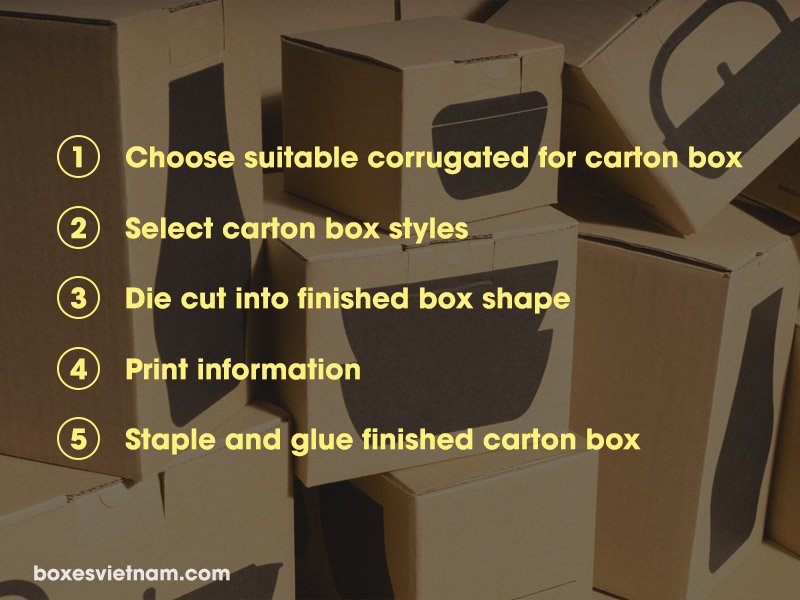

5 steps to produce carton boxes at Khang Thanh

Step 1. Choose suitable corrugated materials

According to part 2, choosing the suitable material is the step that determines the hardness and durability of the shipping boxes.

Khang Thanh will analyze and suggest the appropriate wave type, number of layers and techniques based on the product and customer requirements.

Step 2. Choose the cardboard box style

At this step, we will suggest suitable long carton box designs such as:

- Long two pieces (lid and base) cardboard shipping box

- Snap-lid cardboard boxes on the long side

- Basic folding box

Step 3. Die cut into a finished box shape

After measuring the product and making reasonable calculations, the paper will be cut into a complete shipping box shape.

Step 4. Print information

After cutting the paper, we print information about the product, manufacturer and brand logo on the paper surface. Standard packing boxes printing methods such as offset printing, flexo printing, and silk printing can be applied as required.

Step 5. Staple and glue finished carton boxes

Finally, the manufacturer will staple or glue the parts into a finished packing box and prepare it for delivery to the customer.

Choosing the right long shipping box helps ensure goods are always safe and saves costs.

To save time and effort, contact Khang Thanh for comprehensive solution advice:

KHANG THANH – HOUSE OF PACKAGING

Tel: +84 (0) 77 8878 222

Email: info@khangthanh.com