An important factor that determines the success or failure of a packaging product is printing technology. There are dozens of different printing techniques for paper packaging such as paper bag, paper boxes, carton boxes, labels, manuals, catalogs.

On average, each packaging product has only 2 seconds to attract the attention of a consumer. The first impression is very important, the product packaging makes the customer connect to the product and encourages them to look more closely.

These are the top 5 of best printing techniques for paper boxes:

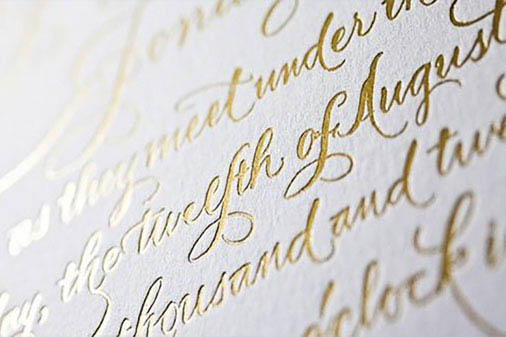

1. Hot metal stamping for box packaging

In the process of printing paper boxes, if you want to emphasize the logo, symbols, text, images on the paper boxes, using hot metal stamping technique is a wise choice.

This technique is very diverse in colors such as gold, silver, blue, red. The most common ones are gold and silver. Stamping technique is often used on high-quality packaging such as paper boxes, paper bags, and catalogs.

Read more: 17 Typical rigid gift box structures

2. Matt / Gloss lamination

When a paper box is finished, in order to keep the colors vivid, crisp, and for the ink to be clear, quality and durable for a long time, the paper nox needs to be rolled through a protective film. The process is called lamination.

There are many different methods of lamination, such as matt lamination, gloss lamination or rib lamination, depending on the needs and purposes of the customer.

In fact, comparing two products with and without lamination, it is clear that laminated paper box product looks more beautiful, luxurious and classy.

Read more: The custom gift box – Special packaging type

3. Letterpress method

Letterpress paper box printing methods are suitable for fine art paper. The printer will conduct embossing and rolling of embossed patterns on the paper to create specific points, depth and accents for the product.

This technique is used for all kinds of highly aesthetic publications such as catalogs, brochures, and magazines.

4. UV coating method

With this method, the surface of the box will be covered with a layer of UV ink. The finished products, under the influence of light, will become more eye-catching. Typically, full and partial UV coating are commonly used in paper box printing.

Read more: Paper Box – The face of every brand

5. Die cutting paper box

This method is to create the custom-shaped paper box products. Khang Thanh printing specialists will create a mold to hold the finished product as required. This is one of the common printing methods used in printing packaging of paper boxes, folding sheets, menus.

Read more: Premium gift box – The modern trend of gift packaging

.jpg)

Khang Thanh – The packaging manufacturer in Vietnam specializes in producing paper bags, carton box, carton offset, labels, hangtag, books, calendar, POSM and so on. Contact us to support your brand with the right packaging:

KHANG THANH CO., LTD – HOUSE OF PACKAGING

Tel: (+84) 77 8878 222

Email: info@khangthanh.com