It can be said that 5 layer carton boxes are a versatile and effective packaging solution thanks to their sturdy structure. Let’s explore why this type of carton packaging has become popular.

1. The definition of 5-layer carton box

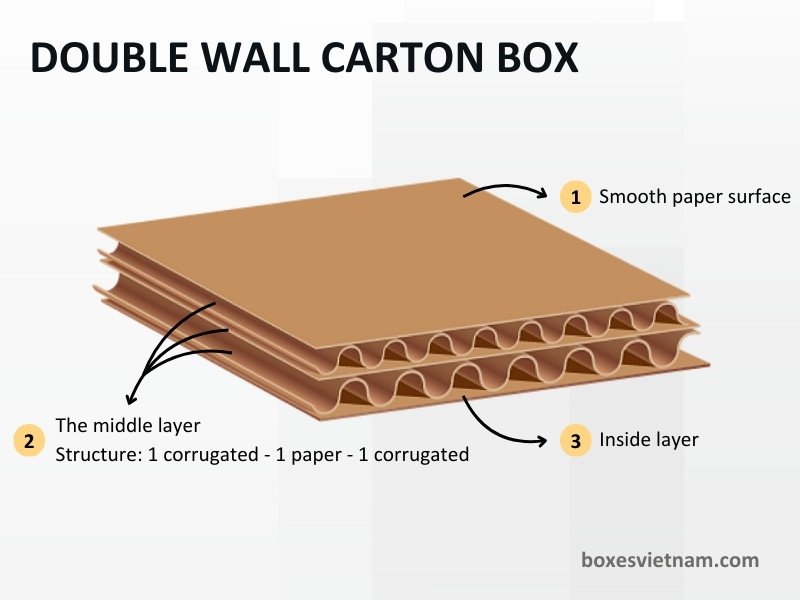

As the name suggests, this is a type of carton with 5 layers, including 2 layers of corrugated paper and 3 layers of flat paper. The paper and corrugated are arranged alternately to create a sturdy, impact-resistant carton structure.

Besides, 5 ply carton boxes are often used to package and transport large products weighing over 15kg, such as furniture, exteriors, refrigeration equipment, and electronics.

2. Structure 5 ply corrugated box

Typically, a 5-layer carton will have the following composition:

- The surface layer is the outermost part of the box, which directly contact with external influences. On this side, a layer of beautiful and smooth paper will be used for printing or coating.

- The middle layer will have a structure of 1 corrugated – 1 paper – 1 corrugated. Typically, 5 ply carton boxes use a double corrugated structure to optimize strength, such as BC flute, BE flute, EE, or EF flute.

- The inside layer is similar to the surface and will be a flat layer of paper. In addition, the inside can be coated with a water-resistant layer or wax if it is a carton packed with frozen goods.

Each layer is important and has its own use, complementing each other to create a complete five-layer carton.

>>> Using cardboard shoe box for saving the environment

3. Advantages and limitations

Advantage:

- Good-price double wall carton boxes will be optimal and cost-effective when mass production.

- The sturdy structure is suitable for packing large loads, minimizing impact and risks during transportation.

- Producing highly recyclable packaging is a way to demonstrate business responsibility and environmental protection.

- 5 ply carton boxes meet international requirements which opening up opportunities to export goods.

Limit:

- Only suitable for humid environments if carton moisture has been tested before production.

- With a 5-layer structure, cartons of this type are often heavy which increasing shipping costs.

- They are not optimized for packing lightweight items such as fashion, shoes, cosmetics, or toys, etc. However, 3-layer cartons will be suitable for these items.

4. Classification and application

5-layer carton boxes are divided into 2 types: unprinted brown carton and offset/flexo-printed carton box.

5-layer unprinted carton (brown carton box, shipping box)

This type’s characteristic is that the cartons are available in common sizes with no information printed on the outside, and they are not used for promotional and commercial purposes.

The 5 most common applications of sturdy and unprinted 5 ply carton boxes include:

- Carton box for packaging goods

- Dosmetic and export shipping packaging

- Waterproof container for storing fruit

- House moving cartons packaging

Eye-catching 5-layer carton with offset/ flexo printing

The smooth surface is suitable for offset or flexo printing to produce high-quality carton packaging. Some industries suitable for producing double wall printed corrugated boxes are:

- Utensils and decorations

- Interior/exterior

- Electronics

- Household appliances

>>> Fasteners packaging solution: Choosing the optimal box types

Khang Thanh with carton production machinery system, is ready to provide standard packaging upon request:

- 3-layer, 5-layer and 7-layer carton box

- Offset printed corrugated box

- Flexo printed corrugated box

- FSC carton box

Explore in detail the multi-layer structure of 5-layer cartons to understand why this type of packaging has become the top choice in packaging and transporting goods. Contacting us for more information about carton packaging:

KHANG THANH – HOUSE OF PACKAGING

Tel: +84 (0) 77 8878 222

Email: info@khangthanh.com